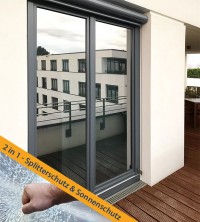

Shatter and solar control film, Heat reduction, 125 µm, silver medium mirrored

- self-adhesive

- Indoor assembly

Price per m² from: €47.20 Price per m²: €42.48 Price per m²: €47.20 incl. VAT plus shipping costs. Item no. 531020

Delivery time approx. 3-6 days

CNC cutting accurate to the millimetre

free assembly tool

| Application | Glass |

| Temperature resistant | -30°C to +80°C |

| Property | mirrored |

| Colour | silver |

| Liability | self-adhesive |

| Material thickness | approx. 125 µm, thick (100 - 150 µm) |

| Mounting side | Indoor assembly |

| Protection from | Sun / Heat, Glass breakage |

Start WhatsApp chat

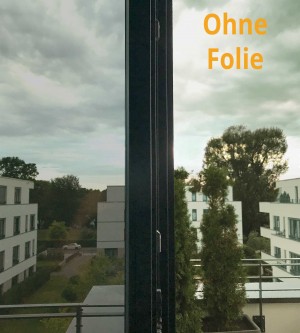

This splinter protection film and sun protection film combines two components at the same time. It offers protection against injuries in case of accidents and also acts as a sun protection film. Due to its good heat reduction and sufficient light transmission, it is suitable for rooms in daily life, as it does not take too much light.

Solar radiation and glare are greatly reduced by this splinter and sun protection film. For example, the rejection of the total solar energy (reduced radiation on the glass) is 75% for the film for interior installation.

In addition, there is the enormously high UV protection of about 99%. This reduces the heating of the rooms, the indoor climate becomes more pleasant, the energy costs for the air conditioning are reduced, the fading of furniture and carpets is reduced and the building experiences a visual upgrade.

Advantages of this film:

- 125 µm (5 MIL) thick protective film

- fulfilsDIN EN 12600,resistance class 2B2

- Fire resistance class M1

- Surface very scratch resistant

- high UV protection (99%)

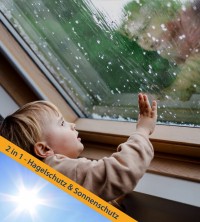

The film is used wherever accidents caused by glass breakage must be prevented, whether in the domestic sector, where e.g. small children are to be protected from glass breakage, or in the food industry, where glass splinters must not be allowed to enter the production process.

Which mounting side is the right one?

As a rule, the splinter protection film should be applied on the side supposedly facing away from the impact. Example: You want to protect yourself in the house against an object being thrown into the pane from outside. In this case, the splinter protection film should be applied on the inside.

The scratch-resistant surface of the splinter protection film makes it easier to clean with standard glass cleaners. At night, when the interior lighting is switched on, a slight reflection appears on the inside of the film.

Included in delivery

You should definitely order the transfer concentrate, art. no. 020010 additionally. It makes the installation easier and leads to a better result. Alternatively, you can also use a pH-neutral cleaner. This must be pH-neutral to prevent streaks from forming together with the film adhesive!Any offcuts are not included in the scope of delivery.

Manufacturer's guarantee

The manufacturer grants a guarantee of 10 years on this splinter and sun protection film when installed vertically and on sloped glazing (skylights) from a roof slope of 25°. This guarantee refers to flaking, yellowing and demetallisation of the film.

Durability

Depending on various factors, the durability of the films is up to 14 years in Central Europe. In the case of sloped glazing such as skylights with a roof pitch of 25° or more, this durability is reduced accordingly due to the stronger solar radiation and the higher exposure to environmental influences.

This splinter and sun protection film fulfils the following standards / properties:

EN 12600 2B2, fire resistance class M1, REACH - RoHS compliant.

| Properties | Indoor installation | ||

|---|---|---|---|

| Light- | Reflection | Indoor | 58% |

| Outdoor | 60% | ||

| Transmission | 18% | ||

| Solar | Reflection | 56% | |

| Absorption | 33% | ||

| Transmission | 11% | ||

| Shading coefficient | 0,20 | ||

| Heat transmission coefficient (U-value) | 5,10 | ||

| Total energy transmittance (g-value) | 0,20 | ||

| Emissivity | n.a. | ||

| UV reduction | 99% | ||

| Glare reduction | 83% | ||

| Total energy rejection (exterior) | 75% | ||

The values of the properties were determined by the film manufacturer. They have been calculated on 3 mm glass using the appropriate methodology and are subject to variations in process conditions in industrial production. They are for estimation purposes only.

| Technical data | |

|---|---|

| Material | PET / PVC composition |

| Film thickness | approx. 125 µm |

| Adhesive | Pressure sensitive adhesive system |

Mounting recommendation

Based on technical data and extensive experience, we can recommend mounting on the following vertically installed glass types:

| Glass type | Number of panes | mainly installed | U-value W/(m²K) | Interior installation |

|---|---|---|---|---|

| Single glazing | 1 (-fold) | until 1978 | 5,7 - 5,8 | yes |

| Double glazing | 2 (-fold) 2 (-fold) 3 (-fold) |

1978 - 1994 1995 - Today 1978 - 1994 |

3.0 - 3.4 1.2 - 2.5 2.1 - 2.4 |

yes no yes |

| Thermal insulation glazing | 2 (-fold) 3 (-fold) |

1978 - 1994 1995 - Today |

1.7 - 2.1 0.4 - 1.4 |

no no |

| Solar control glazing | 2 (-fold) 2 (-fold) 3 (-fold) |

1978 - 1994 1995 - Today 1995 - Today |

1.4 - 2.0 1.0 - 2.5 0.5 - 1.3 |

no no no |

To avoid glass breakage, the entire pane must always be coated with this film; partial coatings are not permitted.

These recommendations may still result in glass breakage due to various factors at the installation site. According to our AGB, §10 paragraph 3 we do not accept any liability for this.

General questions

Can I get a free foil sample?

Of course, please click on this link to access the corresponding order form. You are welcome to add to the list of items if you wish. There are no costs for you!

Will you also cut the film for me?

We cut each film to the exact millimetre according to the dimensions you enter. The cutting is free of charge. You can find detailed instructions on how to measure your panes here.

Alternatively, you can also cut your film by hand with a cutter knife. However, this requires a little manual skill, so you are usually better off using our free service.

Can you also cut a round blank or other geometry?

In general, almost all 2D shapes can be produced. Many geometries (e.g. triangles, trapezoids, circles) can be ordered directly via the online shop. To do so, please click on the orange rectangle to the right of the article image. You can then choose between many different shapes.

For shapes that are not specified, please send us a small sketch (photo) in which you specify the side lengths, radii or angles. Please contact us for this purpose.

Does the film also adhere to surfaces other than glass?

The window film adheres to all surfaces that are approximately as smooth as glass. When applying the film to plastic, please bear in mind that the adhesive may bond with the plastic, making it impossible to remove the film cleanly later.

How can I clean my window pane with the film in place?

You can keep your window pane clean as usual. The film should not be rubbed with sharp-edged objects (e.g. a brush).

You can find more information in our guide General care instructions for window films.

Can the film be removed without leaving any residue?

All window films can be removed without leaving any residue and without damaging the glass surface!

Below you will find detailed instructions on how to remove old window films.

Can you also print on films?

Unfortunately, we do not currently offer foil printing and do not have any partner companies with whom we can realise foil printing.

Assembly instructions for Protective films (self-adhesive)

You will need the following items

- Plastic bottle with hand sprayer, adhesive tape, paper towels (not included)

- Transfer concentrate (not included)

- Glass cleaner (not included) or commercially available glass cleaner

- Installation squeegee and glass scraper blade (included free of charge in the delivery).

Installation tips

- Two people should carry out the installation!

- Do not install any film at temperatures on the installation side below +6° C.

- Fill the spray bottle with 0.5 litres of water and add the transfer concentrate (30 ml) (enough for approx. 6 to 7 m² of glass surface).

-

Thoroughly clean the glass with commercial or our glass cleaner!

Remove all sticky particles (e.g. paint or fly dirt) preferably with the glass scraper blade. No dirt residues should remain on the glass! - The sandblasting foil consists of the mostly white backing paper and the actual sandblasting foil.

Now place the sandblasting foil with the view side down on the glass pane or similar. You are now looking at the back of the film.

Then carefully and slowly peel off the backing paper at as shallow an angle as possible until it is about halfway along the entire length of the film. Cut the backing paper and stick it back onto the sandblasting film with a gap of about 2 cm to the remaining backing paper. - Now hold the in place while the 2nd person

starting from the corner, and at the same time spray the adhesive side of the that is now exposed with the liquid.

Afterwards, the glass pane (surface to be pasted) must be sprayed with the liquid. Do not be sparing with the liquid, the film and pane should be well wet. - Place the on the glass, the film should slide back and forth well, otherwise spray the glass again.

- Now spray the other side of the as well, this will make it easier for you to work with the mounting squeegee.

- Now press the liquid out evenly with the mounting squeegee from the centre to the right and to the left. Make sure that there is no residual water left under the film! Repeat this procedure several times to remove even invisible water residues. When doing this, wrap the supplied squeegee with a paper towel to avoid any scratches.

- Carefully wipe the edges and the foil with a soft cloth. If necessary, press the edges again with the mounting squeegee.

- Now let the dry for three days without touching it.

- Wait two weeks before cleaning the film for the first time and never use hard objects (brush or blade) to clean it. Commercially available glass cleaners can be used.

FAQ`s about the installation

Can I carry out the film installation alone?

For larger pieces, it is recommended that two people carry out the installation. This makes it easier to handle the film and place it on the pane.

How can I avoid dust inclusions under the adhesive back side?

In addition, do not lay the after peeling off (covers the adhesive side for transport) on the floor to get it wet. Rather, pull a table nearby to spray the film on. On the floor you will always stir up very fine dust particles, which will then settle on the adhesive side facing upwards. These dust particles can later show up on the pane under the , which is something to avoid.

Can I apply the without transfer concentrate?

We strongly advise against the use of water diluted with detergent. This can lead to streaking due to a reaction with the film adhesive.

Does the film have to be applied perfectly to the glass at the first attempt?

After mounting, small bubbles formed the next day

In any case, you should wait this time and do nothing. In most cases, the blisters disappear all by themselves!

How easy is it to remove the film?

It is possible that residues of the film adhesive remain in some places. These can be soaked with our adhesive remover or acetone and then removed again with a glass scraper or ceramic field scraper. You will find detailed instructions on how to remove window films on our homepage in the FAQ`s.

We will be happy to send you a free sample of this and up to four other films without obligation.

The samples are approx. 9 x 9 cm in size and will be sent to you free of charge and without obligation by letter post.

|

1. select sample (max. 5 pieces)

|

||

|

Shatter and solar control film, Heat reduction, 125 µm, silver medium mirrored Art.-Nr. 531020 |

|

|

Please select at least one sample!

|

||

- Germany

- Austria

- Switzerland

- Belgium

- Denmark

- France

- Gibraltar

- Greece

- Ireland

- Italy

- Liechtenstein

- Luxembourg

- Malta

- Monaco

- Netherlands

- Norway

- Poland

- Portugal

- Sweden

- Slovakia

- Slovenia

- Spain

- Czech Republic

- United Kingdom

- United States of America

We have received your foil requests.

The samples are usually sent to you within one working day.

Film specialist, Dirk Bilstein - Application engineer

" I will be happy to give you expert advice on choosing the right film! "

Assembly instructions

Tool for easy assembly

The tool sets and accessories offered by Velken will be very useful for the success of your installation! Adhesive films, electrostatic films, decorative coatings... for each product there is the appropriate tool.

In addition to the assembly video, take a look at the detailed assembly instructions.

Click here to view these question(s).

Rate this item objectively and share your buying experience with other visitors.

As a thank you, we will reward you with a shopping voucher* of up to 10€ for your next purchase.

*Voucher valid for 1 year, redeemable from 30€ value of goods (5€ voucher) or 50€ value of goods (10€ voucher), max. 1 voucher per order, not combinable.

The voucher will then be sent to you by email.

You will receive an email from us after the rating has been activated in which you will find the shopping voucher.

New reviews are activated by us every working day.

The company Velken-Folientechnik GmbH accepts this assignment and ensures the necessary data protection.