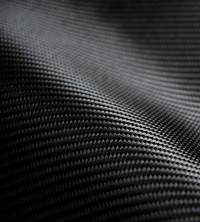

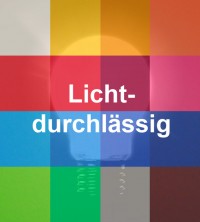

Paint protection film, clear transparent

- self-adhesive

Price per m² from: €34.90 Price per m²: €31.41 Price per m²: €34.90 incl. VAT plus shipping costs. Item no. 593600

Delivery time approx. 5-7 Days

CNC cutting accurate to the millimetre

| Colour | transparent |

| Liability | self-adhesive |

| Protection from | Damage |

| Application | Stone, Bodywork, Wood |

Start WhatsApp chat

This paint protection film has been specially developed for application to vehicle body parts, e.g. mudguards, side skirts, bonnets, load sills, etc. Recommended for application on flat and slightly curved surfaces. This stone chip protection film is characterised by its extreme tear resistance. According to DIN EN ISO 527, it withstands longitudinal and transverse loads of > 34 MPa. The elongation at break was determined to be 550% for longitudinal and transverse elongation. The film is therefore suitable for tough everyday conditions, even brief contact with solvents or chemicals does not affect this stone chip protection film.

Further advantages of this film:

- easy to install and extremely durable

- the surface is very fine and also scratch-resistant

- it does not shrink and does not wrinkle even after years of use

- the film is dirt-repellent and easy to clean

Product information

The surface to be covered must be free of dust, grease or other impurities that could impair the adhesive strength of the material. Newly painted surfaces must be dry or fully cured. Application tests must be carried out with the intended paints to determine compatibility. Do not apply film to repainted car parts, as damage to the paintwork may occur when the film is removed. The repainted paint often does not adhere as well to the filler underneath as the original paint applied at the factory. For further information, please refer to the installation instructions.

Included in delivery

You should definitely order the transfer concentrate, art. no. 020010 additionally. It makes the installation easier and leads to a better result. Alternatively, you can also use a pH-neutral cleaner. This must be pH-neutral to prevent streaks from forming together with the film adhesive!Any offcuts are not included in the scope of delivery.

Durability

The manufacturer indicates a shelf life of 5 years.

| Technical data | ||

|---|---|---|

| Material | Polyurethane film | |

| Film thickness | approx. 130 µm | |

| Dimensional stability (FINAT TM 14) | Bonded to steel max. 0.2 mm shrinkage | |

| Temperature resistance | Bonded to aluminium, -40°C to + 100°C no change | |

| Sea water resistance (DIN 50021) | Bonded to aluminium, after 100 h/23° C no change | |

| Solvent / Chemical resistance |

At room temperature, 72 h after bonding to aluminium briefly resistant to most oils, greases, fuels, aliphatic solvents, weak acids, salts and alkalis | |

| Tensile strength (DIN EN ISO 527) | Longitudinal: > 34 MPa Transverse: > 34 MPa |

|

| Elongation at break (DIN EN ISO 527) | Longitudinal: > 550% Transverse: > 550% |

|

| Retaining adhesive | Solvent polyacrylate, permanent | |

| Adhesive strength | 18 N/25mm | |

| Bonding temperature | > + 10° C | |

Fitting instructions for Paint protection films (self-adhesive)

Procedure

Before bonding the Paint protection films, clean the substrate thoroughly for best results.

Cleaning the substrate

In general, the vehicle substrate should be cleaned with conventional cleaning agents. No agents may be used that serve to create a nano-sealing or nano-coating on the substrate to be cleaned by means of nanotechnology.

- Clean the vehicle in the car wash (brush wash) the day before coating (no hand wash!).

- Thoroughly check the surfaces and edges for residues of preservative wax or polishes and remove these substances with industrial cleaner or silicone remover (isopropanol alone is not effective).

- In general, the surfaces to be covered should be cleaned with isopropanol. This will thoroughly remove any residual cleaner used previously (methylated spirits are not recommended here). Dry the vehicle well and blow out any residual moisture, especially under rubber seals, with hot air.

Note:

Solvent residues resulting from improper cleaning or paint that is too fresh can cause bubbles to form between the film and the substrate and impair adhesion. Ensure that only fully dried and cured lacquers are applied. A guideline is a minimum drying time of three weeks.h4>Film bonding

The manufacturer recommends that only material from the same batch be used for application. If material from different batches is nevertheless to be used, the applicator should check whether batch-related differences have an effect on the application of the films and the result.

Test application

After cleaning the vehicle and before each final application, a test application should be carried out and the final adhesion of the film should be checked after 24 hours. For comparison, it is advisable to apply the film to non-critical surfaces (e.g. window panes) at the same time. If the film sticks too strongly and/or if gas bubbles form, repeat the cleaning procedure as described! Proceed in the same way if the adhesive strength is too low (e.g. if the vehicle or vehicle parts were pretreated with agents that advertise a nano sealant / nano coating or nano technology).

If re-cleaning has been carried out, repeat the test bonding as described above.

Required tools

Bonding tool:

- Film squeegee with felt edge, Art. No. 010150 (not included in delivery)

- Cutter knife, Art. No. 010050 (not included in delivery, order separately if necessary) or standard scalpel

- Heat gun (not included in the scope of delivery)

Processing conditions

- The vehicle must have at least the bonding temperature recommended in the data sheet.

- Clean and dust-free bright room, preferably with lifting platform or assembly ramp.

- Power supply

Preparation instructions

- Measure vehicle parts and generously pre-cut film formats.

- Trimming of the films takes place on the vehicle. A film width of up to 152 cm allows film to be applied to many vehicles without disturbing lugs or overlaps.

- The cutting edge is always the edge of the gap adjacent to the part of the vehicle to be covered.

- Use the resulting overhang of the film in the width of the gap dimension to fold the film over to the interior.

- Avoid cutting the film flush with the vehicle edges to prevent shrinkage of the film as well as mechanical stresses on the open cut edges caused by washing brushes, airflow, etc.

- If the film still has to be cut on the vehicle surface, apply siliconised crepe or similar to the cut edge. After cutting, lift the film slightly and remove the masking tape before applying the film.

Bonding procedure

Stone chip protection films are generally to be processed like calendered soft PVC films. Dry application is recommended for experienced users, otherwise wet application is also possible.

Dry bonding

- Position the film to be applied on the vehicle and fix it with adhesive tape or film remnants.

- Make sure that the film overlaps the edges of the vehicle part to be applied by approx. 5 cm.

- Remove the masking paper from the film and stretch the film evenly over the vehicle part.

- Apply the film to the vehicle in even, sweeping strokes.

- For curved surfaces (e.g. mudguards), heat the film over a large area with a heat gun. Do not get too close to the film with the heat gun.

- Do not trim or wrap the edges until the film has cooled down.

Wet bonding

- Wet application should only be used in the warm season from + 18° C to allow the residual moisture to evaporate quickly and to achieve the required final adhesion.

- The open side of the pressure-sensitive adhesive and the surface to be bonded are sprayed with depressurised water (water + transfer concentrate). To ensure quicker adhesion of the adhesive, add about 20% isopropanol (not benzine or window cleaner) to the mixture.

- The film is placed on the surface to be covered. In this phase, the great advantage is that the film cut can be positioned excellently.

- The film is pressed on with overlapping strokes, making sure that the water is completely wiped out between the substrate and the adhesive.

- In the case of sheet metal overlaps and butt joints of the bonding substrate, the film must be cut through with a sharp film knife in each case so that the film cannot come loose when the substrate moves.

- Any cloudiness in the adhesive that occurs after installation disappears Residual moisture has evaporated and the adhesive has reached its final adhesion.

After completion of the work

The vehicle should be at bonding temperature for at least another 24 hours. A slight haze may remain on dark surfaces. After approx. 3 days, the applied film has reached its optimum final adhesion, so that the vehicle can be driven through a car wash without hesitation. The film-coated vehicle must not be treated with polish for at least 3 weeks after coating. Only wax-free, water-based care products for plastic surfaces should be used. Do not clean a film-coated vehicle with high-pressure cleaners or corrosive chemicals.

Removability

The prerequisite for removability of the films is a substrate and ambient temperature of at least +20° C. The films should be carefully wiped at one corner with a cloth. The films should be carefully loosened at one corner with the help of a knife and slowly peeled off at an angle of 180°. Heating the film at the same time with a hot air blower makes the removal process much easier. In the case of very old films, some adhesive residues may remain on the substrate. These can easily be removed with an adhesive remover.

These processing instructions are based on our knowledge and experience. Not all aspects that need to be taken into account for bonding are explained. The specialist knowledge and skills of an advertising technician or bonder are assumed. Due to the large number of possible influences during processing, bonding and use, we recommend that you test our products in your own trials for special applications. The assumption of a guarantee for the existence of certain properties cannot be derived from our information.

We will be happy to send you a free sample of this and up to four other films without obligation.

The samples are approx. 9 x 9 cm in size and will be sent to you free of charge and without obligation by letter post.

|

1. select sample (max. 5 pieces)

|

||

|

Paint protection film, clear transparent Art.-Nr. 593600 |

|

|

Please select at least one sample!

|

||

- Germany

- Austria

- Switzerland

- Belgium

- Denmark

- France

- Gibraltar

- Greece

- Ireland

- Italy

- Liechtenstein

- Luxembourg

- Malta

- Monaco

- Netherlands

- Norway

- Poland

- Portugal

- Sweden

- Slovakia

- Slovenia

- Spain

- Czech Republic

- United Kingdom

- United States of America

We have received your foil requests.

The samples are usually sent to you within one working day.

Film specialist, Dirk Bilstein - Application engineer

" I will be happy to give you expert advice on choosing the right film! "

Click here to view these question(s).

Habe ein Eura Mobil L 635 von Bauj. 1999! Die Außenwände bestehen aus GFK!

Rate this item objectively and share your buying experience with other visitors.

As a thank you, we will reward you with a shopping voucher* of up to 10€ for your next purchase.

*Voucher valid for 1 year, redeemable from 30€ value of goods (5€ voucher) or 50€ value of goods (10€ voucher), max. 1 voucher per order, not combinable.

The voucher will then be sent to you by email.

You will receive an email from us after the rating has been activated in which you will find the shopping voucher.

New reviews are activated by us every working day.

The company Velken-Folientechnik GmbH accepts this assignment and ensures the necessary data protection.